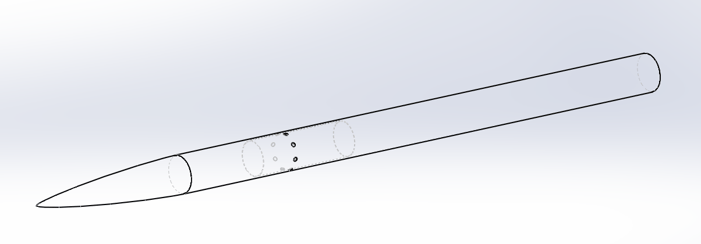

Certain conditions must be met in order for the aircraft to remain in the air and for this to continue in a stable manner. In order to stay in the air, airplanes need a lift force equal to their total weight and in the opposite direction. Airplanes produce this lift force thanks to their wings, as we explained in previous articles. In this context, we can mention that it is critical to design aircraft in accordance with the requirements of wing designs.

However, the lift needed when aircraft moves through the air is not constant, and to provide this variability, engineers have tried to meet this requirement by adding additional surfaces to the aircraft wings. However, surfaces were also needed to create additional drag, not only for transport, but also for slowing down the aircraft when necessary.

Airplanes can have different wing configurations as well as different types of tail configurations according to their needs. However, the main task of the tail is not to produce the required transport like the wing, but to provide stability for different flight states by providing the moment balance of the aircraft. Tail efficiency also needs to be increased in some cases, such as wings, in order for the aircraft to change direction, so additional control surfaces are needed on the tail as well as on the wing.

In this article, we will talk about the additional control surfaces on the wing and tail and their functions.

I. Aileron

Aleron is one of the additional surfaces on the wing. It is not expected to contribute to the transportation, its main purpose is to maintain the moment balance during the flight and to provide the roll movement by creating a moment in the x-axis.

With the opening of one of the alerons and closing of the aleron on the opposite wing, the same directional force couple is formed on the wing in the z-axis, and with the moment created by this couple of forces, the aircraft can maneuver around the x-axis. When needed, there can be 2 alerons on a single wing, one is located in the root region of the wing, the other is closer to the tip region, and the aleron at the wing tip is generally larger in size and the aircraft maneuver is completed by using the aleron required for the moment required for the maneuver.

II. Flap

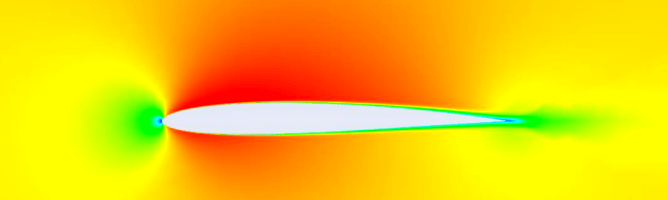

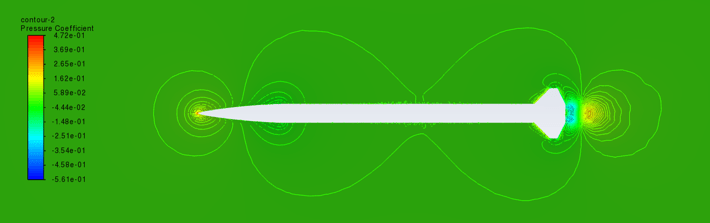

Airplanes need different lift forces for different situations during their movements in the air. In some cases, flaps can be used to increase the lift on the wing.

Flaps basically contribute to the increase of the lift produced by increasing the wing surface area thanks to their movement. When the formulas of the transport and drag coefficients are examined, we see that a derivative related to flap opening affects these coefficients.

There are four types of flaps with different logic:

a. Plain Wing Flap

b. Fowler Wing Flap

c. Split Wing Flap

d. Slotted Wing Flap

a. Plain Wing Flap

The most common type of wing flap is plain. Plain wing flaps are characterized by a basic hinge-like design. In their default state, plain wing flaps remain parallel to the surface of the wings with which they used. Pilots, of course, can adjust them. Plain wing flaps can be lowered to increase drag. Lowering plain wing flaps will result in more drag and, therefore, a slower airspeed.

b. Fowler Wing Flap

Some airplanes have fowler wing flaps. Fowler wing flaps are distinguished from plain wing flaps by their slotted design. All slotted wing flaps have multiple slots through which the air can flow. This slotted design allows the wings to produce more lift. Air can flow through fowler wing flaps more easily so that the wings produce more lift. Commercial jets and other wide-body airplane are oftenly use fowler wing flaps.

c. Split Wing Flap

Split wing flaps aren’t as common as plain or fowler wing flaps. In the past, though, they were often used on military airplanes. And you can still find some military airplanes with split wing flaps. Split wing flaps feature a hinge at the bottom, which allows them to pivot. They can pivot up or down on this hinge.

d. Slotted Wing Flap

The main difference lies in the number of slots they have. While fowler wing flags have multiple slots, slotted wing flaps have a single slot. This single slot is found at the hinge. When a slotted wing flap is extended, the slot opens. This open slot offers a passage through which air can flow.

All airplanes have wing flaps. Some of them have plain or fowler wing flaps, whereas others have split or slotted wing flaps. Wing flaps are simply the adjustable flaps on an airplane’s wings.

III. Flaperon

Flaperon can basically be defined as a piece that can handle the task of flap and ailerone alone. It takes part in both increasing the lift force and stability of the moment balance. It is used in hobby planes and mini unmanned aerial vehicles, as well as on the trailing edge of some commercial aircrafts.

IV. Slat

It is one of the elements on the wing. It contributes to reducing the speed by increasing the drag force on the wing. It is generally used in aerial operational situations that require a reduction in speed – such as landing.

V. Rudder

Rudders are one of the control surfaces on the tail of aircraft. It is located in the vertical tail, called the vertical stabilizer. No lift contribution is expected from aircraft tails in terms of performance. Since their main task is to maintain the moment balance of the aircraft, this movement surface does not contribute to the transport. It is the control surface that is responsible for the rotational motion of the aircraft in the z-axis relative to the aviation axis. This movement is called yaw moment.

VI. Elevator

Like the rudder, the elevator is one of the control surfaces on the tail. It is located in the horizontal tail, which is called the horizontal stabilizer. Basically, its task is to balance the moment movement of the aircraft in the y-axis with respect to the aviation axis. Since it is one of the derivatives of the lift coefficient, it contributes to the transport, although not as much as the flaps, but since it is also a derivative of the drag coefficient, it also creates an increase in drag. As a result, its main task is to provide the pitch moment balance of the aircraft.

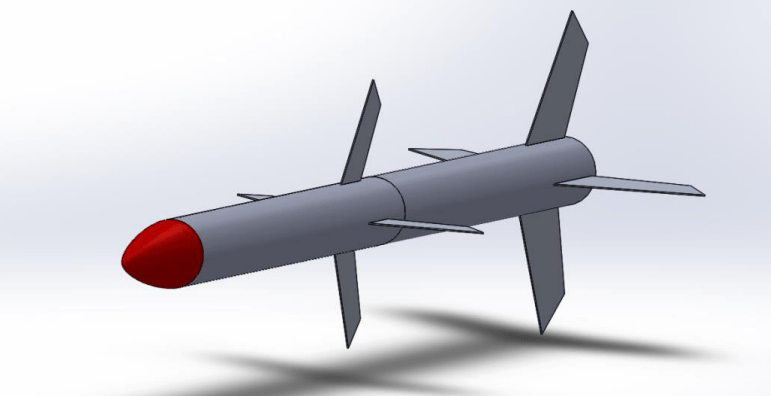

VII. Ruddervator

Ruddervator are a control surface that we usually see on v-tail aircraft. Since the V-tail is a structure that we usually encounter in unmanned aerial vehicles and delta-wing warplanes, it is possible to encounter the radiator in this type of aircraft. As a basic logic, this control surface works as a mixture of radar and elevator. While it sounds good logically, the use of this control surface requires dexterity. In addition, it contributes to the increase in the maneuverability of the aircraft.

VII. Elevon

Elevon basically appears as the control surface of the elevator and alerone mixture. It can be seen in delta-wing aircraft and unmanned aerial vehicles. It is a difficult to use control surface like a radiator, but it also contributes to maneuverability.

The control of all these control surfaces described here is provided by the console and pedals located in the cockpit. It would not be wrong to say that they are easier to use for pilots in more electronic-based aircraft manufacturers such as Airbus. However, piloting mastery is critical.

Stay with science and knowledge.

Writer: Berkay Çakır

Editor: Halit Yusuf Genç